By Cathy Finley

Hemp—one of the most unreasonably demonized crops of all time. Banned in Canada in 1938 for being related to cannabis, legalized again in 1998, hemp is experiencing a resurgence in popularity.

At Laurica Farm, we built a house from hemp. So positive was the experience, we find ourselves advocating for hemp at every opportunity and considering a hemp crop as part of our future farming plans.

We’ve waxed lyrical numerous times about the potential of this crop and the multitude of uses and benefits, from its performance as a healthy food to hemp plastic cars! But it’s producing fibre hemp to utilize as a building material that is of most interest to us.

When we were in the research and design process, one of the questions that kept coming up as we drove around looking at cookie-cutter, insufficiently insulated and poorly performing homes was “is this really the best we can do?” Our learning in “doing better” has exceeded all of our expectations. Even my husband, an experienced builder and commercial contractor, has added a wealth of experience and knowledge to his existing skill base. The house itself is, without question, one of the greatest and most rewarding achievements of his career. And, after leaving the construction industry feeling disenchanted, it is the building he is most at peace with, feeling confident that this structure is carbon negative. Most of all, this is a building that does not compromise our values.

“Sustainable” doesn’t mean the same to us as it does to writers of building code and municipality building services. A huge part of our budget was spent on professional services, including having to hire an Envelope Consultant as hempcrete does not have CSA approval. No one in our local building services office had ever heard of hempcrete and we spent three months finding an Envelope Consultant that would even look at this project. So much time was expended trying to get some professional or another to understand the product. Every tradesman that has worked on this build has commented that they’ve learned something.

“Sustainable” doesn’t mean the same to us as it does to writers of building code and municipality building services. A huge part of our budget was spent on professional services, including having to hire an Envelope Consultant as hempcrete does not have CSA approval. No one in our local building services office had ever heard of hempcrete and we spent three months finding an Envelope Consultant that would even look at this project. So much time was expended trying to get some professional or another to understand the product. Every tradesman that has worked on this build has commented that they’ve learned something.

But, despite the numerous set-backs, the benefits of this build far outweigh the challenges.

Using hemp to build is an ancient idea that is experiencing a revival. Hempcrete started making a solid comeback across Europe and New Zealand in the 1980s but it has taken until now to gain popularity in North America. It is rare for a “new” material to be introduced into construction—insulation options have been the same for decades.

As we demand better performance from our buildings, the amount of oil-based insulation we use escalates; and, as safety standards increase, the amount of chemical input needed exceeds what is healthy for us (some fire retardants are known carcinogens). According to Green Building Canada, “about 200,000 new homes are built each year, with an average footprint of 2,000 square feet. If they were all insulated to code minimum requirements with hempcrete, a total of 990,718 tons of carbon could be sequestered annually. If the same homes had walls with fibreglass insulation, 207,345 tons of carbon would be emitted to create that insulation, so the total net carbon savings for the planet is significant”.

Most live in air-tight homes that are off-gassing toxins into living spaces. It seemed common sense that we would choose to meet the need for insulation with an easily-renewable, natural, toxin-free, alkaline biocomposite. After much research, building with hempcrete was the only way we could mitigate toxic and leachable chemicals entering our home. Not only that but hemp itself is grown organically, and the crop does not require pesticides, so it is kind to the earth and environment as it is produced.

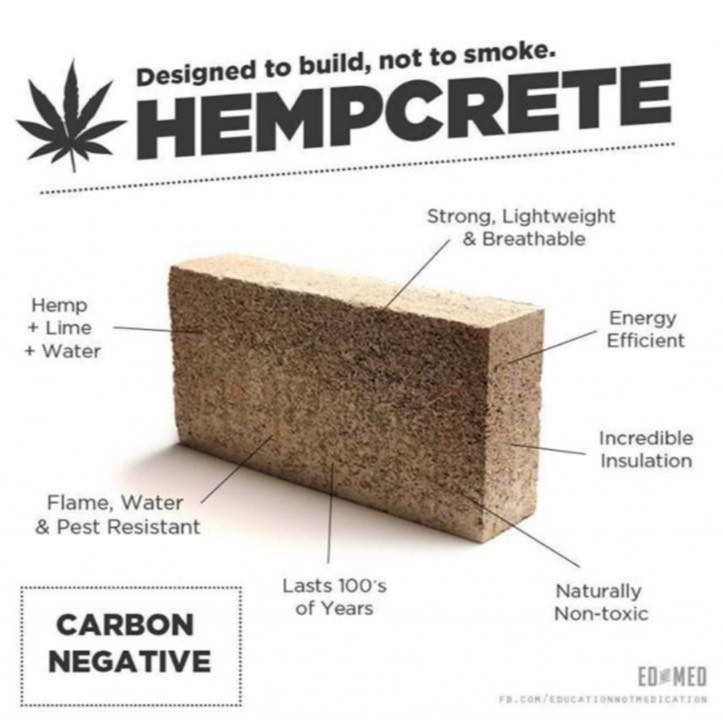

To make hempcrete, the hurd or shiv of the plant (an agricultural bi-product) is mixed with lime and water. Hemp is a renewable biomaterial and lime is a natural and abundant mineral. When mixed together and formed into a wall, they combine to make a building material that gets stronger over time, continues to sequester carbon, doesn’t burn and is so alkaline that rodents and pests won’t touch it. The house is strong with 12-inch thick walls, but if there is ever need to take the house down it can be composted and returned back to the earth, unlike other insulation.

Using hempcrete makes for an incredible clean and safe building site. You have to be aware that it is alkaline and that can irritate skin, eyes and airways, but the process of building with the material requires little mechanical input. There are no huge concrete trucks pouring caustic concrete—just us and a team of helpers mixing with an onsite mixer, filling buckets and pouring into double-framed walls.

There is no skin in this structure and no worrying about where the thermal mass goes. This building is vapour permeable (it allows water vapour to pass through). The air pockets in hempcrete absorb moisture when there is high humidity and release it again when humidity decreases.

There are a couple of benefits in having a house that passively regulates itself. There is no condensation or mould spore—another element that is harmful to our health and well-being. And self-regulating indoor air quality eliminates the need for mechanical ventilation. In fact, we positioned the walk-in fridge on the north elevation of the building where there is minimal sunlight. Add this to hempcrete’s ability to regulate and you get a functioning refrigerator operated with no mechanical input, electricity or power, further reducing energy costs.

One thing everyone wants to know about is cost. This house cost around 10% more to construct (including professional services) than a conventional home. We have opted for green materials throughout—not just hempcrete. We prioritized eco-friendly things like magnesium oxide board instead of drywall, non-toxic osmo oil as opposed to stain, LED lighting, and bamboo flooring. So, was it worth the extra expense? Yes!

The house performs so efficiently that it costs us almost nothing to run. We have yet to collect data but the owner of a hempcrete house in Ashville reports that his house costs 24 cents (US) per day to run. We also believe that as greener materials become more easily accessible, the associated costs will reduce.

But we must also drive the rhetoric to give value to other benefits as well as cost—environmental, health and well-being. We cannot find a material that has such low-embodied energy and creates such a healthy living environment as hempcrete. We all have a responsibility to make better choices for our future, and hemp can play a major part in cleaning up our act.