Home owners who live in close proximity to larger agricultural operations understand there are both positives and negatives that go along with rural living, but most would say they would prefer to live without the overwhelming odours sometimes created during necessary on-farm activities.

And, indeed, most agricultural operators do use good farm practices, and are concerned about reducing the impact on their neighbours as much as possible.

According to West Coast Environmental Law’s (WCEL) website, “Farmers cannot be sued for nuisance-type impacts to nearby landowners, such as noise and odour, from normal farm practices. Residents living in farming areas must be willing to accept both the pleasant and not-so-pleasant byproducts of an agricultural community.”

Normal farm activities may be protected from nuisance complaints, but when enough residents are negatively affected by odours emitting from agricultural or industrial operations, local governments can institute bylaws to reduce offensive odours, and administer fines.

“For example,” states the WCEL site, “Abbotsford’s Farm Bylaw regulates storm water management, wastewater management, and on-farm composting. It includes 30 metre setbacks for compost facilities and storage of compost/agricultural waste, and removal of 90% of the odour from the exhaust from compost facilities.”

Pursuant to the Farm Practices Protection (Right to Farm) Act, the Ministry of Agriculture, Food and Fisheries (MAFF) is assigned the responsibility to receive and attempt to resolve nuisance concerns (e.g., dust, odour, noise or other disturbances) relating to farm practices.

In some Lower Mainland areas, the continuing spread of residential development alongside agricultural land will result in greater potential for nuisance complaints by the non-farm residents. Stricter governance around odour from farming operations might be inevitable as the number of complaints increases; meanwhile, keeping the peace over this issue is left to the individual operator/owner.

Doug Lanz, President of Air Phaser Environmental Ltd., says, “There are technological solutions that can be incorporated into many farming operations to reduce odour or eliminate it completely. And one technology might be more optimal than another, or they can be combined for the best solution.”

“The type of odour abatement system we offer is likely a little more investment than a smaller agricultural operation would like to make,” admits Lanz, “however, it is just the technology needed when operations get to a larger scale. In such situations, odour can impact neighborhoods, devaluing property and cause enough complaints that it becomes political. These issues can be avoided with the proper equipment and good planning.”

In the following section, Lanz describes a recent system installation in a commercial-scale marijuana greenhouse—which can produce strong odours—to explain how the innovative technology works.

Odour Abatement System Installation in a Marijuana Greenhouse

Cold plasma is a scalable technology that uses a modest amount of electricity to convert odorous compounds into non-odorous forms through a process known as oxidation.

A cold plasma field is created when high voltage and medium frequency is applied to electrodes that have an air gap which causes micro electrical arcs to form in the air gap. This electrical, micro-arc activity causes a wide range of very reactive compounds to form.

These compounds are mixed with odorous air, react with the complex, odorous compounds, and oxidize them so that they are transformed to simpler molecules that are non-odorous. It is important to note that these hydroxyl compounds are many more times reactive than simple ozone, which is also reactive and will also neutralize odour to a certain extent; however, ozone is not nearly as effective as hydroxyl compounds.

During a recent system installation, a marijuana greenhouse was divided into 2 sections, each having separate temperature control for ventilation. Section A vented 7,000 cubic feet of air per minute (CFM) when the temperature exceeded a certain point (thermostat controlled) and Section B vented 8,000 CFM using its own thermostat.

As the thermostats and their controlled blowers were independent, the air volume could be from Section A, or B, or A & B. This means either 7,000 cfm, or 8,000 cfm or 15,000 cfm would need odour treatment.

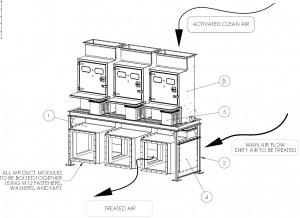

The odour control system design uses a dedicated set of plasma electrodes and high voltage/medium frequency transformer (HVMFT) for each section, both controlled from a single control panel. A simple Programmable Logic Controller (PLC) was used to monitor each section’s thermostat and an air flow sail switch to determine when each section was venting. The PLC also controls the cold plasma power inverter which powers each HVMFT through a control relay. This way, individual section cold plasma control was enabled, with an air flow sail switch used to confirm blower operation for fail safe operation.

Other automated safety devices were implemented, all made easy by using a PLC for the control. The system also controls the speed of a common vent blower that disperses the air once it goes to the roof exit.

The surprising feature of this odour control system was how little energy was needed to neutralize the odour using cold plasma. When both systems ran to treat the full 15,000 cfm air flow, the cold plasma power was only 0.2 watts per cfm, or 3,000 watts. In a facility that had about 1000 square foot plant area per section, this represents the amount that three lights would use. Also, the control interlock with the air ventilation system means that it automatically starts and stops.

Air Phaser Environmental provides equipment demonstrations, electrical and mechanical drawings needed for installation, and commissioning and personnel training. The equipment is compact, modular and can be adapted to many industries.