The Future of Robotics in Agriculture

By Tom Baumann, Associate Professor at the University of the Fraser Valley

Who’s going to look after our robots, fandangled machines and electronics? Automation Technicians, of course…

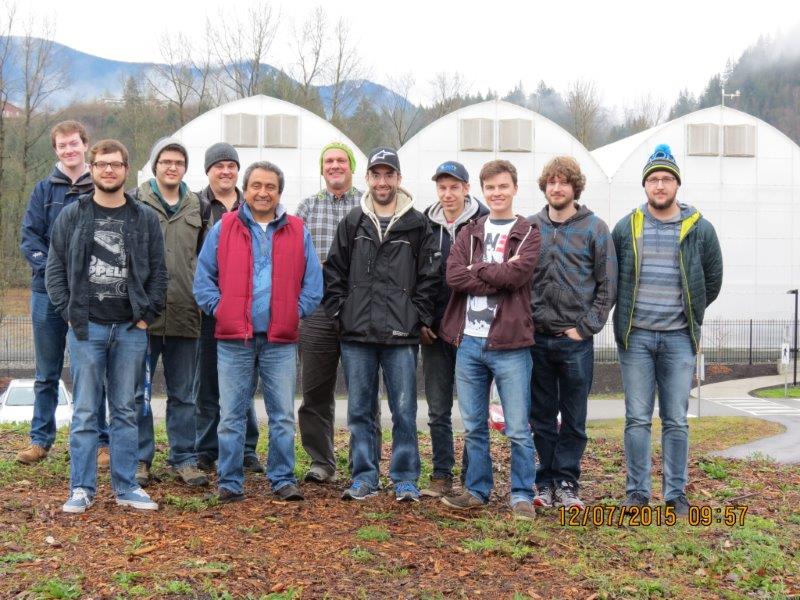

I sat writing this article as my students wrote their final exam for the introductory agriculture course designed for the Automation Technician Program at UFV. The program was approved just recently and is in response to a need in our industry to keep up with the advancements in on-farm mechanics and electronics. The agriculture industry, known to employ many labourers who work long days, is quickly being transformed into a technological wonderland.

What exactly is automation? We all know that to automate a process one figures out how it is done by hand, then duplicates the process with either a portion of the process or the entire process done by machine. Just like Henry Ford automated the process of building a car, we are automating processes such as harvesting of corn, grains, berries, eggs, milk and much more. Industry is in need of specialists that will install, maintain, and troubleshoot automation.

What are the Drivers of Automation in Agriculture?

We are forever striving to produce more food, more ornamental stock, more industrial supplies and even natural fuels from agriculture. In that process, we are not able to find qualified, or even unqualified workers to fill every single job; plus, some jobs are now requiring knowledge of electronics and robotics. With our society having decided—and, rightfully so—to protect workers and to make sure repetitive injuries are prevented, and to reduce labour costs, we have strived to automate processes for the more mundane tasks.

Ever since Jethro Tull (NOT the music group) wrote the book on agriculture in the “modern age” during the 1600s and early 1700s, the seed drill, plows, and horse drawn implements became the norm. After the Second World War, competition from countries with cheap and plentiful labour forces created a need for Canada to stay ahead or lose our own agriculture production and the food security for which we all strive. Nowadays with global market competition, labour cost and laws—including taxes to allow our society to function—we must become incredibly efficient to stay competitive.

Types of Automation in Agriculture

Let’s talk examples. The following lists the type of automation systems the students saw in the course of their education:

- Dairy farm: robotic milkers, round bale hay balers, huge carousel milking parlours, self-setting implements, self-cleaning milking implements.

- Nursery: cart systems from producer to end user, automated labelling with point-of-sale data tags, propagation machinery, automated irrigation systems, and robots as a recent demonstration by BCLNA introduced.

- Sweet corn operation: several row full harvesters, automated sorting and standard bin movement throughout operations.

- Greenhouse manufacturing plant: modern robotics for forming the super structure and cladding materials.

- Chicken farm: automatic feeders and waterers, computer-controlled mechanisms, egg-sorting, cleaning and checking devices.

When the students were halfway through writing their exam I peeked at their work for inspiration on what to write next. In the first section I asked them to comment about the field tours and I listed some of their answers as I looked over their shoulders.

“Dusty, dry, wet, cold, hot” were some of the words the students used to describe the indoor and outdoor environments they visited. Some substances they expected to encounter might be “fertilizers, cleaning chemicals, disinfectants” and the like. They learned that safety rules, including biosecurity, are to be taken very seriously so they can protect themselves, the crops, the food safety of the final product delivered to the market and the end consumer.

As for the types of automation they expected to encounter in agricultural work, the students put down so many it is impossible to list them all; needless to say, all the ideas either already exist or are about to break into mainstream agriculture. I was astounded just how much these young students had researched this topic in preparation for the exam. They suggested so many more possible automations than those of the producers we visited. They identified who might make decisions on purchasing, installing and maintaining automation machinery and electronics, and the range was wide.

On the other hand, the students also pointed out the limits of automation such as price point, and resistance to something new.

The Future of Ag Tech

I also wonder what the future holds. I envision technologies depicted in science fiction such as Star Wars and Star Trek: Terraforming machinery, global weather control nets, sensors in every single plant to report back on the state of growing, food production facilities with not a single person around. These visionaries surely weren’t thinking on a small scale, but a global one! Some may view this advancement as a drawback for jobs, or as new jobs being created—such as automation technicians that make sure the operation runs like a well-oiled machine.

When the students were asked what impressed them the most about modern agriculture, GPS precision guided machinery, robotics, and electronics were the clear favorites. The disappointment was that agriculture hasn’t quite adopted available technology; but they expressed that lately agriculture has been on the forefront of new developments such as drones and LED lighting, and they hope that these trends continue. One only needs to see a blueberry sorting plant with laser colour-sorters and soft-sorters working at a speed that no human could to be convinced that automation is the future. Only by adopting new technology will blueberry producers be able to market over 150 million pounds of blueberry fruit a year in BC alone.

Most interesting were the student’s answers when asked where they see themselves in this industry after graduation. Except for one, they were sure they’d work in agriculture in areas of innovation, invention, implementation or maintenance and trouble shooting. This is very encouraging as industry needs these specialists in a big way as we move forward and adopt another wave of automation that elevates the quality and quantity of our food production when every nation will struggle to provide water and food.

We will find more agricultural solutions from the next generation of innovators, forward thinkers and technicians that will keep us operating. Looking at their answers, I believe my students are on their way to playing a very important, integral role in the future of agriculture. And I am grateful and pleased to be part of the process, educating students about the needs of our industry. What is certain it that we need highly motivated, highly qualified technicians now, on the ground!

More information on UFV’s automation technician program: https://www.ufv.ca/automation/

[infobox title=’Tom Baumann’] Tom Baumann has spent most of his agriculture career as a horticulturist specializing in berries. His company, Expert Agriculture Team Ltd., provides many services to others including advice, trouble shooting and aids in claim situations. Tom also teaches full-time at UFV Chilliwack as an Associate Professor in the Agriculture Department.[/infobox]

Tom Baumann has spent most of his agriculture career as a horticulturist specializing in berries. His company, Expert Agriculture Team Ltd., provides many services to others including advice, trouble shooting and aids in claim situations. Tom also teaches full-time at UFV Chilliwack as an Associate Professor in the Agriculture Department.[/infobox]